Let loose the Power of Accuracy: Get the Perfect Dirt Screen for Sale Today

Let loose the Power of Accuracy: Get the Perfect Dirt Screen for Sale Today

Blog Article

Optimize Recycling Performance With Advanced Dirt Screens for Arranging and Separation

And one crucial option that has actually acquired traction is the usage of innovative dirt screens for arranging and separation. And possibly most intriguingly, what are some real-life success stories showcasing the transformative power of innovative dirt screens? Join us as we explore these inquiries and even more, uncovering the best methods for executing these displays and reinventing reusing methods.

Advantages of Advanced Dirt Screens

Advanced dust screens offer countless advantages in improving reusing efficiency. One of the key advantages of innovative dust displays is their ability to remove impurities and impurities from the recycling stream.

Furthermore, advanced dirt displays add to ecological sustainability by enhancing the overall high quality of recycled products. By guaranteeing that unpolluted and only tidy things proceed to subsequent processing phases, these screens aid to produce higher-grade recycled items with boosted market demand. This not only promotes the circular economic climate however likewise minimizes the reliance on virgin products, lowering and saving all-natural resources carbon discharges.

How Advanced Dust Screens Work

To understand exactly how dirt screens function, it is essential to understand the fundamental principles behind their operation. Advanced dirt screens are developed to efficiently different dust and debris from recyclable products, thereby maximizing the recycling procedure. These screens use a combination of mechanical and gravitational pressures to accomplish this job.

The operation of innovative dust displays begins with the feeding of combined recyclable products onto the screen surface. As the products relocate along the display, they run into various sized apertures or openings. These apertures enable smaller bits and dirt to pass through while keeping bigger recyclable things.

The display surface area is typically inclined at an angle, enabling gravity to assist in the separation procedure. As the materials relocate down the display, the bigger and larger recyclables proceed to travel, while the lighter dust and particles are brought away by gravity and fail the apertures.

Additionally, progressed dirt screens are equipped with resonance systems that assist to promote the separation procedure. These vibrations aid to loosen and dislodge dust fragments, ensuring that they can conveniently travel through the apertures.

Secret Features to Look for in Dust Screens

When picking dirt displays, it is very important to think about essential functions that improve efficiency and effectiveness in the reusing procedure. These functions play a critical duty in optimizing the screening and splitting up of products, making sure a better result and decreasing downtime.

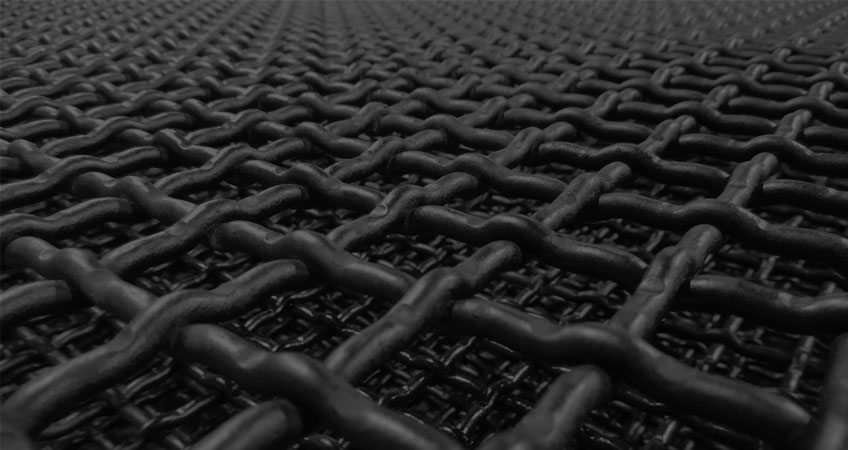

One trick feature to try to find in a dust screen is the shapes and size of the screening openings or mesh. The appropriate hole dimension is vital for efficiently dividing dust and other unwanted materials from recyclable products. It needs to be huge sufficient to enable efficient material circulation yet little enough to avoid beneficial recyclables from going through. Additionally, the form of the testing openings can influence the testing performance. Round holes tend to be extra efficient in stopping clogging contrasted to square or rectangular openings.

Another crucial attribute to take into consideration is the material and construction of the dirt screen. Screens made from long lasting and top notch materials such as stainless-steel or polyurethane are extra resistant to tear and put on, leading to a longer life expectancy and decreased maintenance costs. The construction of the display, including its reinforcement and support framework, should also be sturdy sufficient to hold up against the demands of the reusing procedure.

In addition, the layout and layout of the dust display must help with very easy accessibility for maintenance and cleaning - dirt screen for sale. Screens with quick-change mechanisms or quickly exchangeable panels can reduce downtime throughout upkeep

Study: Success Stories With Dust Screens

Several instance research studies have actually demonstrated the success and effectiveness of using dirt displays in the reusing sector. These studies have showcased how dust displays can dramatically enhance recycling efficiency by eliminating contaminants and boosting the pureness of recycled blog materials. One instance research study performed by a reusing facility in the United States located that including dust displays into their arranging process caused a 25% boost in the healing price of recyclables. By efficiently separating dirt, rocks, and various other debris from the recyclable products, the facility was able to produce cleaner and higher-quality recyclables, which ultimately resulted in raised market demand and boosted productivity.

One more study, conducted by a recycling plant in Europe, focused on the benefits of utilizing sophisticated dirt displays in the separation of glass from other recyclable materials (dirt screen for sale). By carrying out dirt screens with flexible setups, the plant achieved a much more exact separation process, resulting in a significant reduction in glass contamination within other recyclables. As a result, the plant experienced improved arranging efficiency, decreased waste, and increased general recycling rates

These study highlight the favorable impact that dust displays can have on reusing operations. By properly eliminating dirt and various other pollutants, these screens contribute to higher-quality recyclables, increased healing prices, and boosted profitability for recycling facilities.

Executing Advanced Dirt Screens: Finest Practices

The successful application of sophisticated dust displays needs mindful factor to consider of ideal techniques and sector criteria. To maximize reusing performance, it is vital to follow a set of standards when applying these displays.

Second of all, it is crucial to guarantee that the dust screens are appropriately sized and mounted within the recycling system. This involves thinking about variables such as the flow rate of waste materials, the dimension of particles to be screened, and the offered room within the center. Proper setup will maximize the effectiveness of the screens in eliminating dust and impurities.

In addition, normal upkeep and cleansing of the dust screens are important to make sure ideal efficiency. This consists of regular assessments, elimination of any kind of gathered particles or obstructions, and changing damaged components as essential. By sticking to an upkeep routine, the displays can continue to operate effectively and efficiently.

Finally, it is recommended to stay informed about industry criteria and advancements in dust display innovation. This understanding can assist recycling facilities stay in advance of the contour and make notified decisions when implementing advanced dust displays.

Final Thought

In final thought, the use of advanced dust displays can significantly enhance recycling efficiency by enhancing sorting and splitting up procedures. A number of success tales highlight the performance of implementing dust displays in click over here recycling centers.

Advanced dust go to my site displays offer countless advantages in boosting reusing effectiveness. Advanced dust displays are developed to efficiently separate dust and debris from recyclable materials, thus enhancing the recycling procedure.The operation of advanced dust screens begins with the feeding of combined recyclable products onto the display surface. These researches have showcased how dirt displays can substantially enhance reusing effectiveness by removing contaminants and increasing the purity of recycled products.In verdict, the usage of innovative dirt screens can greatly optimize reusing efficiency by improving sorting and separation procedures.

Report this page